Agronomic Resources | Wheat Profit Podcast | Fusarium Resources | Wheat Midge Resources | Harvest Resources | Durum Production Manual

Harvest Resources

Pre-Harvest Applications in Wheat

Staging wheat for pre-harvest weed control can be tricky, especially in years when the crop is uneven due to poor conditions. Pre-harvest staging is critical to avoid any herbicide residues in the grain, which can lead to Maximum Residue Limit (MRL) and marketability issues. A wheat plant is considered physiologically mature at 30% moisture; this means grain fill has stopped and final yield and kernel weight/size has been determined. Spraying pre-harvest products such as glyphosate, prior to 30% grain moisture can negatively impact grain quality and marketability.

Click the image above to open a PDF document or click here to read more

Research has shown that the application of glyphosate at the soft dough stage (>30% moisture) had negative impacts on kernel weight, protein content, and end use quality (Malalgoda, et al. 2020). The application of glyphosate can halt the physiological maturation of the plant, which can disrupt grain fill and can lead to decreased yield and quality, if the application is made prior to hard dough stage (< 30% moisture). It can also result in unacceptable product residues in harvested grain and cause marketability issues.

Maximum Residue Limits and Pre-Harvest Intervals

MRLs represent the maximum amount of a pesticide that can be expected to remain on a food product (such as wheat) when the product is used according to label specifications. MRLs are not a representation of food safety, they are used primarily for trade purposes to ensure Canadian crops meet MRLs set by export countries.

Pre-Harvest Intervals (PHIs) are the minimum amount of time required between the application of a pesticide and harvest or swathing. Following PHIs can help to ensure that there will be no unacceptable residues in harvested grain. They can be found on product labels and in the 2022 Guide to Crop Protection.

Always check the label and follow the application rate, timing, and PHI to avoid any market access issues.

Assessing 30% Moisture

Most pre-harvest products are applied at 30% moisture. Here are the steps to assess 30% in wheat:

- Go to the least mature area of the field. It is important to stage the field for pre-harvest product applications in this area because it is the most likely to have residue issues. It is very important to stage based on the least mature area of the field, and not just the field average, to avoid any MRL issues. If the least mature area will delay harvest too long, skip this area with pre-harvest products and combine it later.

- Assess the plant for physiological maturity. This can be done by looking at the peduncle, which is the part of the stem directly below the head. If it is still green the plant is not ready for a pre-harvest application. Once this area turns yellow, the plant is likely getting close to physiological maturity. It is important to confirm the plant has reached < 30% moisture by performing the thumbnail imprint test in the next step. Figure 1 shows the progression of colour change on the peduncle.

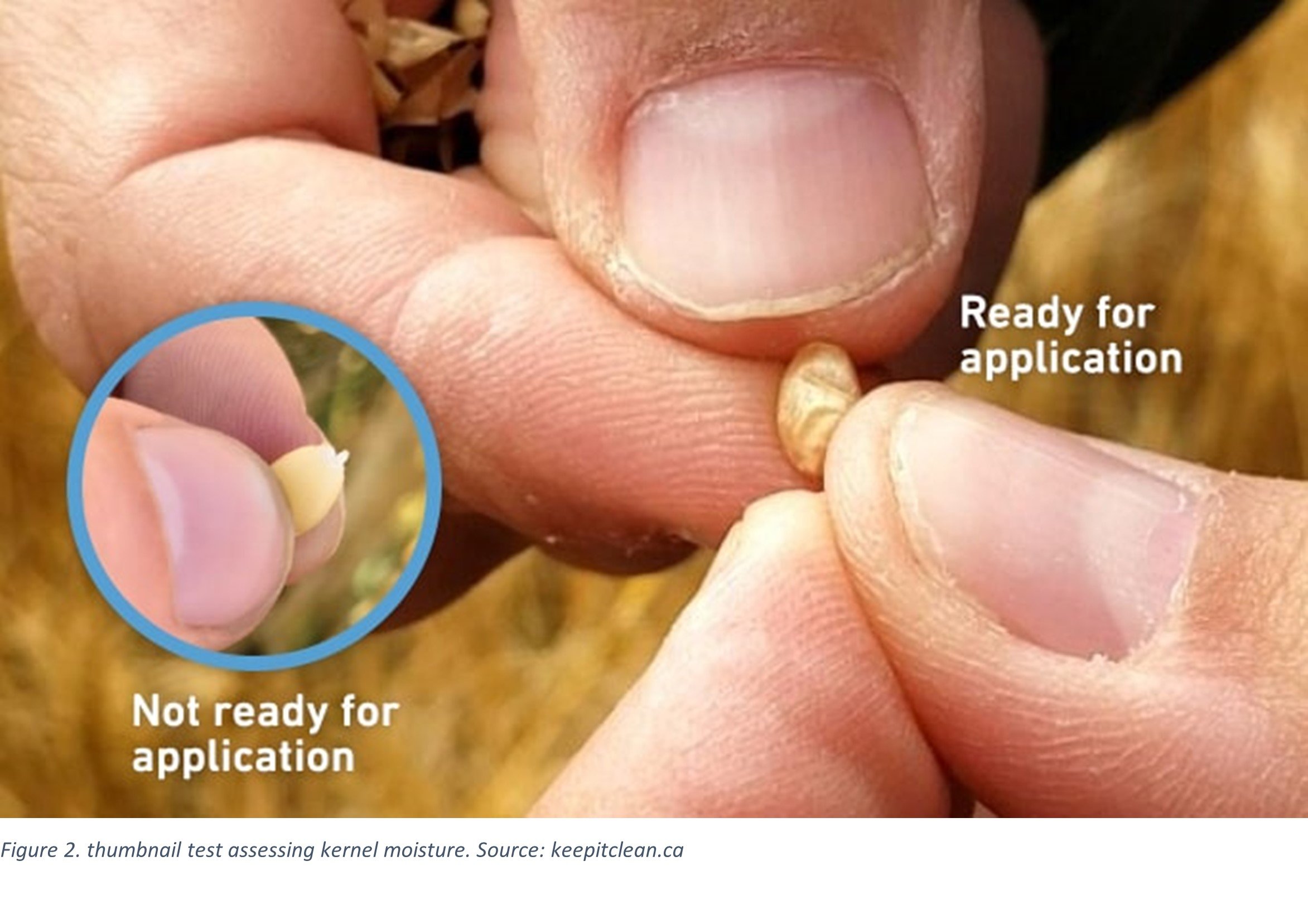

- Thumbnail test on kernels to confirm < 30% moisture. To confirm the plant has reached physiological maturity, assess the kernels. Shell out a wheat head in your hand and apply pressure to a kernel with your thumbnail. If the imprint remains, the grain is < 30% moisture. If the indent does mot remain in the kernel, the crop is not ready for pre-harvest application. Preform this test on multiple heads and in multiple areas to confirm the field is at the proper stage.

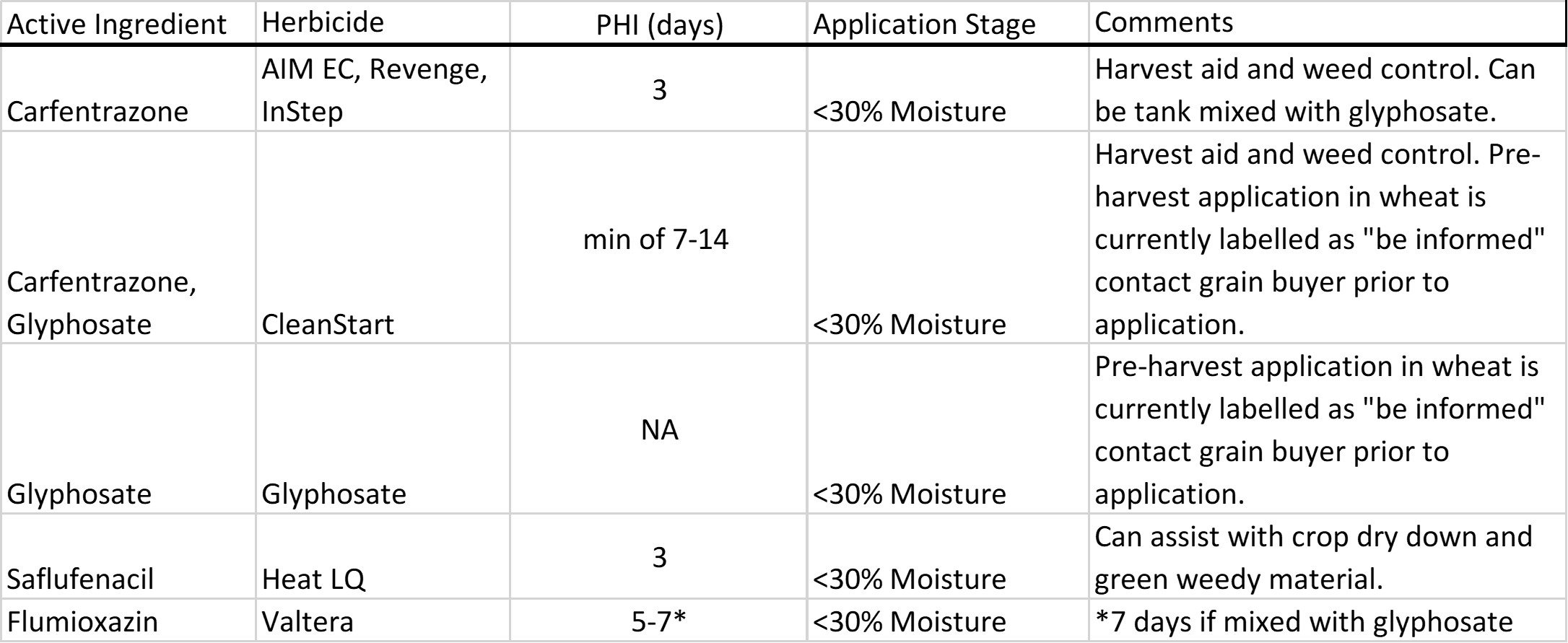

Pre-Harvest Products Registered in Wheat

Always check with your grain buyer before applying pre-harvest products to ensure there are no trade concerns domestically or internationally. Some customers have contract limitations on fall applications of glyphosate, so have a conversation with your grain buyer to ensure they know what protection products you intend to use and to confirm that none of these products will cause concern for export or domestic customers.

When choosing a product for a pre-harvest application, it’s important to consider what the product is registered for. Products that are registered for harvest aid, like carfentrazone (AIM EC®) and saflufenacil (Heat®), can help speed the rate of dry down in crops and green, weedy material. Harvest-aid products are contact herbicides, which means only top growth is controlled. Some contact herbicides can be tank mixed with systemic herbicides (glyphosate) prior to harvest for better weed control. However, the rapid activity of contact herbicides can significantly reduce the movement of glyphosate into perennial weeds and therefore reduces the efficacy.

Products that are registered for pre-harvest weed control are designed to kill actively growing weeds, not to hasten the maturity of the crop. Glyphosate is not a desiccant; it is registered for pre-harvest weed control. Pre-harvest weed control products, like glyphosate, help with harvest by reducing the amount of green weed material. These products are systemic herbicides, which are most effective when applied to actively growing weeds. This is because systemic herbicides can be absorbed and translocated into the roots of perennial weeds to provide better control.

It’s important to check the label of any pre-harvest product for rate, timing, and PHI to avoid any residue issues. Be aware of market restrictions on pre-harvest products and talk with your grain buyer to ensure the products you are using won’t create market access issues.

Additional Resources

Keep it Clean: Cereals

Understanding Preharvest Intervals

2022 Guide to Crop Protection

Sources

2022 Guide to Crop Protection, Saskatchewan Ministry of Agriculture.

Malalgoda, Maneka, Jae-Bom Ohm, Joel K. Ransom, Kirk Howatt, and Senay Simsek. 2020. "Effects of Pre-Harvest Glyphosate Application on Spring Wheat Quality Characteristics" Agriculture 10, no. 4: 111. https://doi.org/10.3390/agriculture10040111

Where allowed, glyphosate is registered for pre-harvest weed control and is not to be used as a desiccant.

Keep it Clean is reminding Canadian canola, cereal and pulse growers that careful management of pre-harvest glyphosate applications can help ensure crops meet the needs of domestic and export customers.

Applying pre-harvest glyphosate for weed control too early can result in unacceptable product residues in harvested grain, which can create market risk.

Your on-farm practices make a difference in protecting Canada’s reputation as a trusted supplier of high-quality canola, cereals and pulses. Visit the Keep it Clean website for more information on managing pre-harvest glyphosate application to reduce market risk.